On the Russian passenger liner MS-21, it is planned to introduce a system for monitoring the state of structures.

Nikolai Lvov, General Director of the IRT Research Center, announced this.

“We have signed a roadmap and a plan, now the terms of reference for the implementation of the system on MS-21 are being developed,” he said in an interview with TASS.

According to Nikolai Lvov, this real-time monitoring system will monitor, among other things, the condition of the MS-21 composite wing, made entirely of Russian materials.

As noted on the website of the IRT Research Center, the monitoring system includes fiber-optic sensors for measuring various physical quantities, on-board unit recorders (electronic equipment) and special software for processing and analyzing information recorded by sensors.

“Monitoring systems are designed to record real-time loads acting on structures, detect damage, including impact damage, in controlled structures, assess pre-failure conditions and residual life,” the company says.

According to the developers, the introduction of such systems today is extremely relevant due to the active use of new composite materials in the aviation industry and the need to study them for impact resistance and the occurrence of internal cracks.

“While vast experience was accumulated with old materials, special theories were developed for the development of cracks, metal resistance, but for composites this experience was absent.

This was not only our problem.

This is a problem that the whole world has been and is working on,” Vladimir Kargopoltsev, scientific director of the IRT Research Center, told TASS.

As noted in the company, the sensors of the system continuously monitor the condition of significant structural elements of the machine, which allows you to monitor the situation from the onset of defects to the development and appearance of cracks and a possible violation of the integrity of structures.

Thanks to this, technical services get the opportunity not only to check the condition of the machine, but also to understand the history of the problem, as well as to predict the remaining life of the aircraft and the onset of a pre-failure state.

The IRT Research Center reported that a similar system is already being used on the Ka-52M combat helicopter.

The information received by aircraft technicians from the Ka-52M includes data on the performance of the main elements of the helicopter's structure, including their residual life.

In addition to the MS-21, the monitoring system can be implemented on other domestic aircraft.

In particular, the Ilyushin Design Bureau became interested in the development of the IRT Research Center.

“The company is most interested in integrating the system into the Il-76 aircraft at the first stage,” said Nikolai Lvov, Director General of the IRT Research Center.

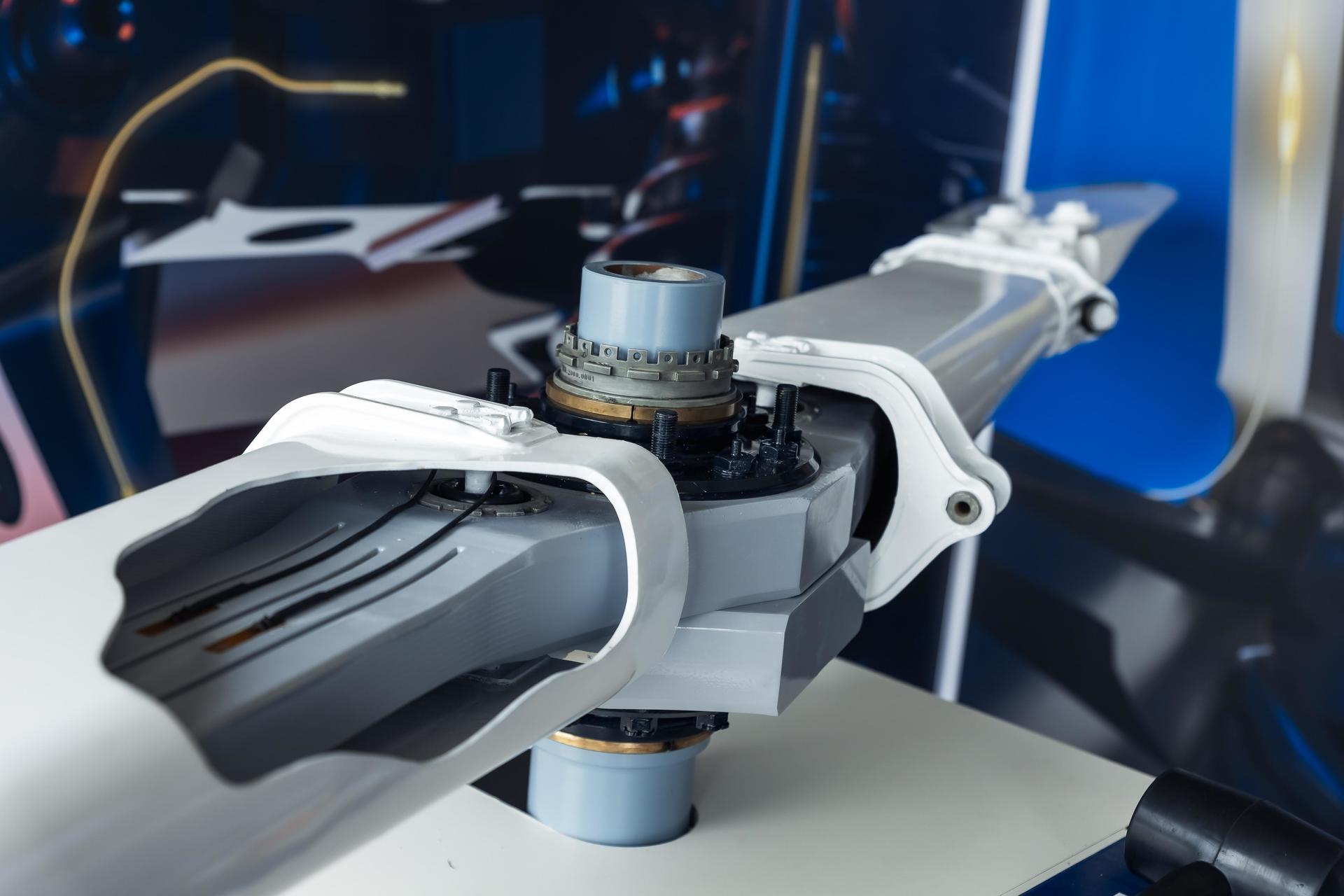

Demonstration of the concept of operation of control sensors of the Research Center "IRT" at the forum "Army-2021"

© Press Service of the Research Institute "IRT"

Get on the composite wing

Recall that the MS-21 is a medium-haul narrow-body passenger airliner developed by the Irkut Corporation.

The share of composites in the MS-21 structure is about 40%, which is a record figure for ships of this class.

It is worth noting that initially, when creating the liner, imported composite materials were also used, but their supply became impossible after the US imposed new sanctions against the Russian Federation in 2018.

As a result, the production of composites was established in Russia, which affected the timing of the project.

According to Rostec, domestic materials for load-bearing composite structures were developed with the participation of scientists from Moscow State University and Rosatom enterprises, and the wing consoles and the center section of the MS-21-300 aircraft are manufactured at the AeroComposite-Ulyanovsk enterprise.

MS-21 with an all-Russian composite wing made its first flight in December 2021.

MS-21

RIA News

© Nina Padalko

But Western sanctions affected not only composites: in 2022 it became known that American power units for the MS-21 would not be supplied to Russia.

Initially, it was assumed that the first serial liners would fly on American Pratt & Whitney (PW140) engines, and in parallel with this, a version of the MS-21 with Russian PD-14 units, which were created specifically for this liner, would be designed.

However, due to American restrictions, aircraft with PD-14s had to go into production immediately, which also pushed back the deadlines for completing the work.

The first experimental liner with PD-14 took off in December 2020.

In October of this year, the first flight was made by the second sample MS-21 with PD-14.

Moreover, this aircraft was previously tested with an imported power plant, but then it was remotorized.

According to Andrey Boginsky, UAC Deputy General Director for Civil Aviation, General Director of the Irkut Corporation, connecting the second aircraft to testing will increase flight density and continue tuning the engine and on-board systems for their most efficient operation in the MS-21.

He also said that certification of the MS-21 with a Russian engine is expected to be completed before the end of 2022.

For the production of MS-21, it is planned to modernize the equipment of the relevant industries.

On October 17, Prime Minister Mikhail Mishustin announced that the Russian government would allocate about 15 billion rubles for equipment for aircraft factories producing the domestic MS-21 airliner, so that the country would produce at least 36 such aircraft per year.

As Deputy Prime Minister, head of the Russian Ministry of Industry and Trade Denis Manturov noted in August, the completion of all work on the creation of a fully import-substituting version of the MS-21 is expected by the end of 2024.

One of the main customers of the MS-21 will be Aeroflot.

At a meeting in August with Russian President Vladimir Putin, the company's general director, Sergei Aleksandrovsky, said that the company intends to purchase 210 MS-21 aircraft.

"Based on new technological principles"

As the retired Major General Vladimir Popov, Honored Military Pilot of the Russian Federation, noted in an interview with RT, as part of the creation of the MS-21 in Russia, for the first time in our country, mass production of aircraft with the widespread use of composites will be launched.

Under these conditions, the system for monitoring the condition of such materials is highly demanded in the industry.

Instruments in the cockpit of an MS-21-310 airliner with a PD-14 engine on the territory of the Flight Research Institute named after M.M.

Gromov in Zhukovsky

RIA News

© Nina Padalko

“The wing consists of a center section and two huge consoles that house the engine, fuel tanks, wing control units and other elements.

All this forms certain operating conditions for composite materials, which must be observed.

And to observe not periodically, as we do with designs that have worked out well, but constantly.

The more information we get about the state of this or that material, the more reliably we will design and create new models in the future,” he said.

According to Vladimir Popov, aircraft design checks have been carried out before, but this was not done in such a comprehensive format and not in large numbers.

“The planes had engine control devices for the temperature of the exhaust gases, for the degree of gas compression on the compressor, or for the degree of pressure passing through the entire engine tract.

In especially loaded places, special sensors were installed for pressure, load and bending.

But they were not so massively used, there was no technological possibility to make them compact enough and build them into the design.

Now, on new technological principles, it has become possible.

This leads to greater flight safety, ”the expert emphasized.

In turn, the editor-in-chief of the portal Avia.ru Roman Gusarov noted the importance of the MS-21 for domestic civil aviation.

In his opinion, the MS-21 is the aircraft that will become the main workhorse of our civil aviation for the next 40-50 years.

“MS-21 is in the most demanded segment of civil aviation — medium-haul single-aisle narrow-bodied aircraft.

Therefore, it is difficult to exaggerate or downplay its importance for our civil aviation and for the entire aviation industry as a whole, ”the expert said in an interview with RT.

A similar opinion is shared by Vladimir Popov.

“This will be a model that can shape the image of our civil aviation.

This is the first swallow.

On its basis and technological innovations, the entire system of domestic civil aviation will develop, ”concluded the analyst.