On this site, historically specialized in antibiotics, amoxicillin is manufactured, a widely used treatment, especially in children: in the latter, it even represents 70% of antibiotic prescriptions, for example for ear infections.

Amoxicillin - which is one of the penicillins - comes in two forms, both prepared in Mayenne: either the molecule alone or in combination with clavulanic acid, intended to promote absorption by the body.

On fully automated production lines, white powder fills glass vials at a rate of up to 120 vials per minute.

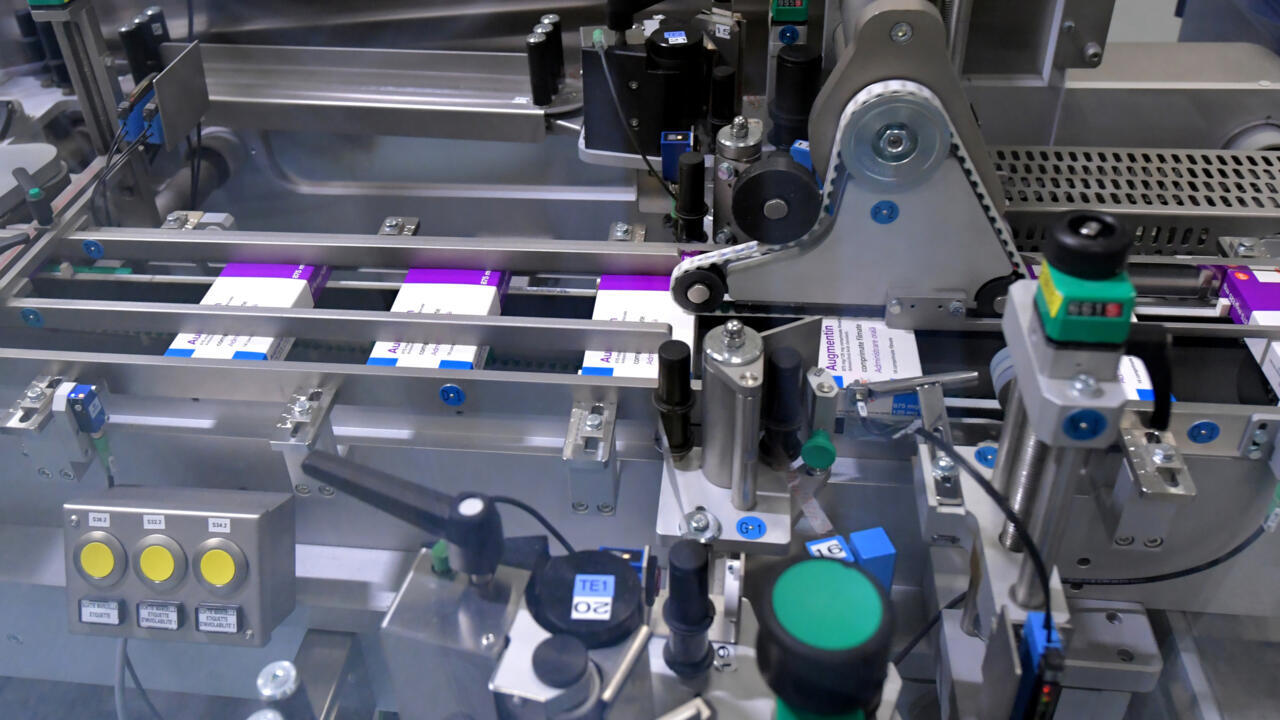

The drug, which is also produced in other forms, in tablets, capsules or sachets, is then packaged and transferred to 110 countries around the world, while 28% of production remains in France.

The factory, whose production rate had declined at the height of the pandemic, is once again operating at full speed, at maximum capacity.

The 370 employees take turns day and night, five days a week. Because demand has jumped since the pandemic has receded.

According to data from the Gers (group for the development and production of statistics for the pharmaceutical industry), 45 million boxes of amoxicillin were sold in 2020 in France, compared to 63 million dispensed from January to November 2022.

An employee with a packet of Augmentin tablets at the GSK pharmaceutical factory in Mayenne, January 5, 2023 © JEAN-FRANCOIS MONIER / AFP

Recruit

The shortage problem is global.

Because winter ailments, which had greatly decreased with the confinements, are back, with a magnitude that had not been foreseen by the laboratories.

France, Spain, Australia and the United States have been sounding the alarm for several weeks now, particularly for pediatric forms.

And the tensions could last, warned the Minister of Health François Braun, Thursday, according to whom it will take another "two months to be really quiet and to have our stocks replenished".

Concretely, for GSK, this means doubling production over two years, and going from 45 million boxes produced in 2021 to a target of 87 million boxes in 2023. "We have gone from 1.1 million boxes produced per week to two million every week, since September", testifies Christophe Wadoux, the director of the Mayenne factory.

For this, it was necessary to hire nearly forty people last year, and recruitment is not over: "We should reach 440 employees in all on the site by the end of 2023", he says.

The GSK pharmaceutical factory in Mayenne, January 5, 2023 © JEAN-FRANCOIS MONIER / AFP

"Recruitment is our number one priority, knowing that we are in a pool of full employment", adds the director of the Mayenne site.

This lack of manpower is the reason why the factory has not switched to weekend production.

Because it takes four to six months to train a manager of a production line, specifies Mr. Wadoux, who foresees that the manufacture of amoxicillin will remain durably superior to before the pandemic.

For its part, the French National Medicines Safety Agency authorized the manufacture of amoxicillin directly by certain pharmacists a few days ago, while other laboratories are investing to produce more.

Sandoz, the generic drugs division of the Swiss Novartis, has thus implemented specific actions at its Kundl site in Austria, in particular the hiring of additional staff, in addition to additional investments.

"The sense of urgency was given by the situation in France and in the world", comments Mr. Wadoux, who says his teams mobilized by a situation which "touches" them.

© 2023 AFP