Scientists from the National Research Technological University MISiS, with the participation of specialists from the North Caucasus Federal University (NCFU), have created a complex for the spectral analysis of diamond materials that has no analogues. This was reported by the MISIS press service.

The technology makes it possible to determine important characteristics of diamonds without interference and defects. For the first time, the researchers combined three types of spectral analysis into a single complex: Raman and FTIR spectroscopy, as well as spectrophotometry.

Raman spectroscopy makes it possible to assess the effect of heat treatment on the change in the diamond structure. FT-IR spectrometry is effective for determining the shape and amount of nitrogen impurities in the crystal structure. The spectrophotometry method is used to study diamond coatings and allows one to determine their quality and the presence of nitrogen defects.

- Installation for the synthesis of diamonds

- © NUST MISIS

According to the developers, these methods do not affect the research object and do not change its properties. At the same time, they do not require complex preparation and, when used in combination, significantly surpass other common methods, which have a number of disadvantages.

For example, spectral analysis using a carbon electrode has a destructive effect on the material under study. and prevents the interpretation of defects. The study of the impurity composition using X-ray spectral microanalysis requires long-term preparation of samples and equipment, and the study on microscopes focused on the detection of boron and nitrogen impurities in diamond is economically disadvantageous and does not have sufficient accuracy, the researchers note.

With the help of a new complex of spectral analysis, in addition to determining the authenticity and purity of natural diamonds, it is also possible to reveal all the characteristics of materials necessary to obtain high-quality artificial diamonds by chemical vapor deposition on substrates (diamond plates), scientists say.

“In our work, a lot depends on the raw materials that are usedfor the production of diamond. From the purity of gases, defectiveness, structure and roughness of diamond substrates ", - says the project manager, head of the research laboratory of superhard materials NUST MISIS Nikolai Polushin.

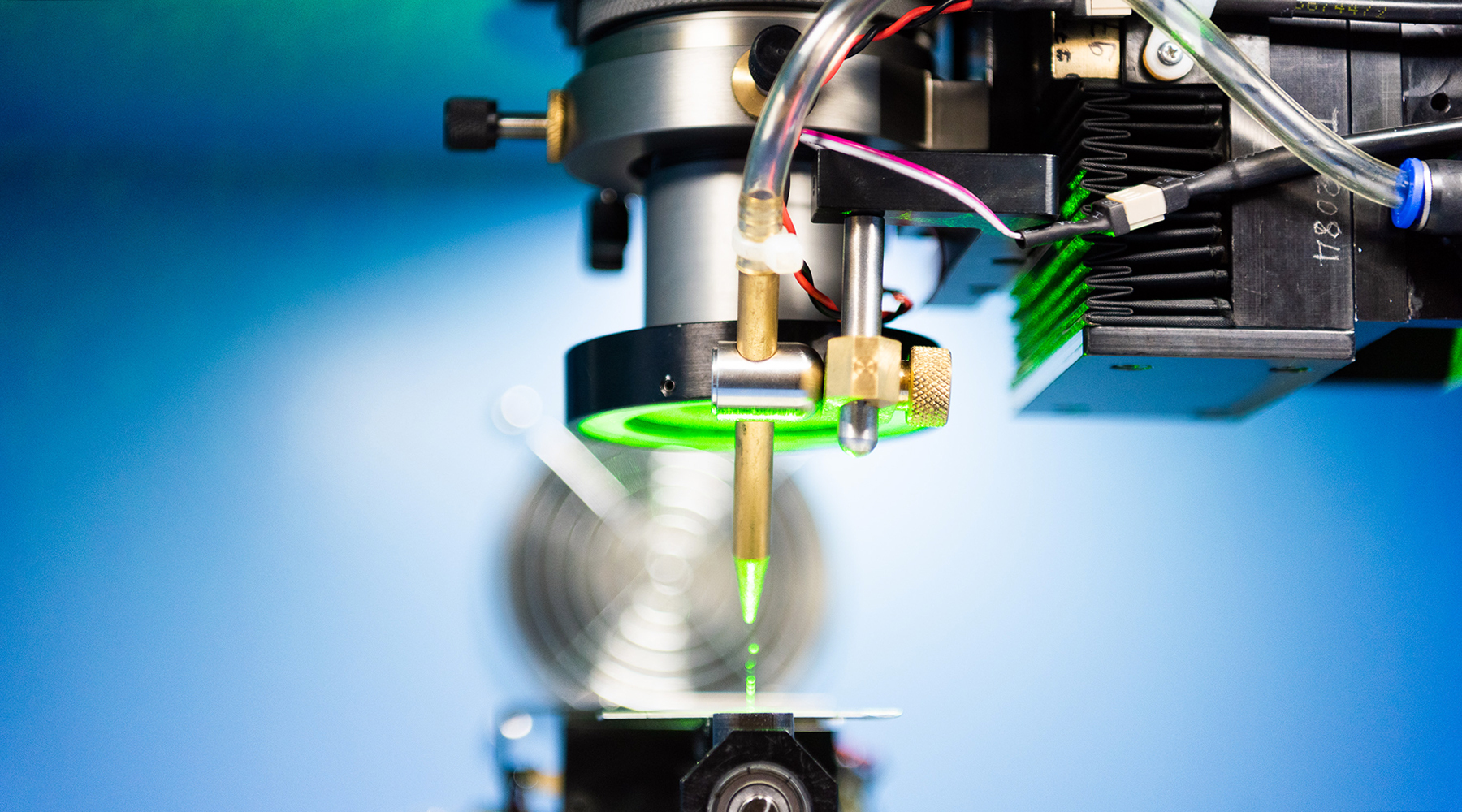

- Diamond laser cutting: removal of build-ups on the sides of a synthetic crystal

- © NUST MISIS

The data obtained thanks to the new complex makes it possible to select diamond substrates for the production of high-quality polished diamonds weighing one and a half carats, scientists say. Also, using the developed technology, unique diamond materials have already been manufactured for use in scientific instruments - detectors of heavy charged particles and neutrons and high-power solid-state lasers.