Physicists from ITMO University have created a technology for applying labels from silicon nanoparticles to goods to protect against counterfeiting.

This was reported to RT by the press service of ITMO.

The results are published in ASC Applied Nano Materials.

When creating labels, scientists used the method of laser ablation - the so-called removal or transformation of a substance on the surface of a material using laser radiation.

In addition, laser ablation is used to obtain silicon nanoparticles.

The authors of the work acted with laser pulses on a silicon film superimposed on top of glass.

As a result, silicon nanoparticles were formed, which remained on the surface in the form of a special mark.

Although the general shape of such an image (for example, in the form of a logo) can be programmed, each label will be unique due to the properties of silicon nanoparticles.

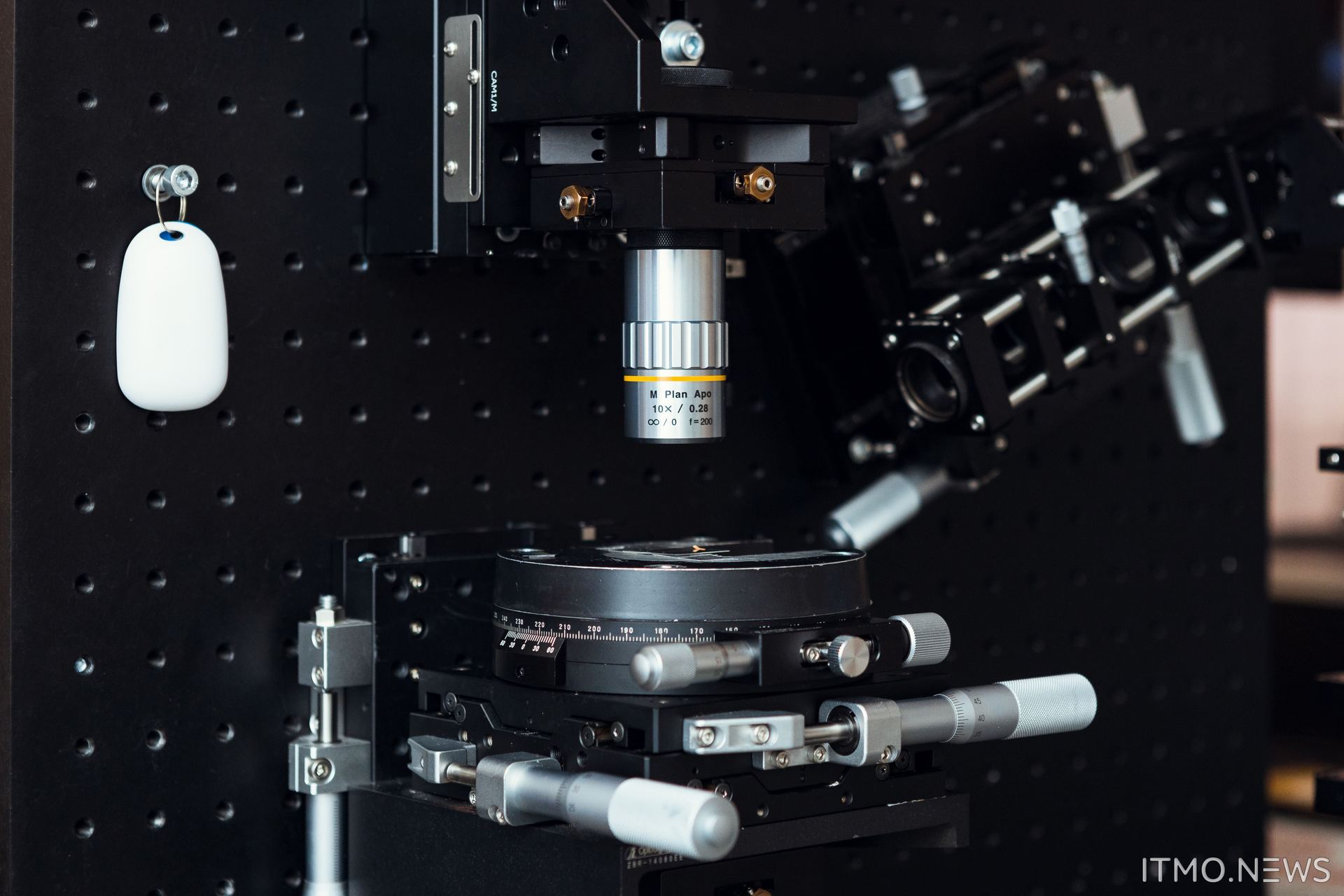

The PHAROS laser system used to create marks

© Dmitry Grigoriev/ITMO.NEWS

“The laser affects the silicon film, as a result of which nanoparticles are “knocked out” of it, which randomly form a texture.

The final picture resembles a cluster of multi-colored stars, ”said Pavel Kustov, the first author of the article, a graduate student of the New Institute of Physics and Technology at ITMO, in an interview with RT.

Each particle has its own parameters - coordinates (location on the glass), color, and structure.

The shape of the label is formed from the particles and their location in total - this is the first level of protection.

The color characteristics and structure of each nanoparticle provide second and third levels of protection.

All data is encoded and entered into a special database.

The label applied to the product is not visible to the naked eye, experts say.

To view and check it, you need to take a photo and upload it to a special program.

Project authors: Elena Petrova, Pavel Kustov and Martin Sandomirsky

© Dmitry Grigoriev/ITMO.NEWS

The computer algorithm first aligns and simplifies the image, and then compares it with the data in the database.

“If all the parameters match, the program will issue a verdict that you have the original.

If there are too many differences, it will indicate a fake, ”explains Elena Petrova, co-author of the study, student of the New Institute of Physics and Technology at ITMO.

The authors of the work did not accidentally choose silicon - this material is resistant to external influences and gives a large color gamut.

Silicon tags in the future can be applied to various surfaces.

According to scientists, the development will be in demand among manufacturers of goods produced in limited quantities: medicines, cars, jewelry, musical instruments.

“In the international scientific space, there are very few studies that offer affordable and easily implemented technologies for creating non-cloneable security labels.

The laser ablation method and silicon are used for these purposes for the first time.

It turned out that a relatively simple method can provide the maximum level of protection.

The next step in the project is to make our tags more flexible in order to expand the range of materials they can be applied to,” concluded Martin Sandomiersky, co-author of the article, student at ITMO’s New Physical and Technical Institute.