Scientists of the National Research Technological University MISiS have developed a technology for obtaining a high-strength material - nanostructured iron, which retains high welding properties.

The use of such iron will make it possible to abandon bolted joints and, due to this, significantly reduce the weight of the metal structures being created.

The development is reported in the Journal of Materials Processing Technology.

Traditionally, to obtain a high-strength material, additional chemical elements are added to its composition, which significantly deteriorates its weldability during processing at factories.

MISIS scientists decided to go a different way, applying the technology of changing the internal structure of iron.

On the installation of severe plastic deformation, iron is pressed.

The repeated pressing process leads to a significant refinement of the metal grains to the nanoscale level.

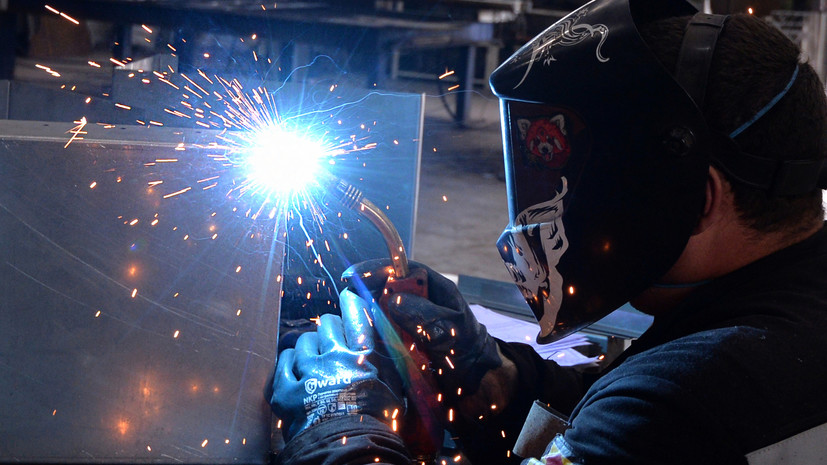

The new nanostructured ARMCO-iron surpasses traditional iron in mechanical properties, while maintaining high performance during welding, allowing the creation of strong joints.

This opens up the possibility of using welding instead of bolted joints, which, coupled with the high strength of the material, can lighten the metal structure by one and a half times.

The development will find the greatest practical application in the automotive and aircraft industries, the scientists are sure.

Also, new prospects are opening up in the study of nanostructured materials, since the problem of their weldability has practically not been studied before.

"The study of the technological properties of nanostructured metals, such as weldability, will allow, firstly, to unambiguously determine the scope of these materials, and secondly, to significantly expand this area," said Alexander Komissarov, head of the research laboratory of hybrid nanostructured materials at MISIS.

In the near future, the team will continue researching nanostructured iron using other welding technologies, various materials and production methods.