Scientists from NUST MISIS have printed 3D parts of complex shape with ultra-thin walls from tungsten, RT was told in the press service of the university.

The 3D printing technology used tungsten powder, which was melted with a laser.

As a result, the researchers obtained a part with ultra-thin walls with a thickness of 100 micrometers (0.1 mm).

For comparison: the thickness of a human hair can reach 120 micrometers.

“Tungsten, due to its refractoriness (melting point - 3422 ° C. -

RT

) and brittleness, is one of the most difficult metals to process.

For example, the well-known tungsten filament for incandescent lamps is produced by drawing wire at high temperatures.

However, there are actually no methods for manufacturing complex volumetric products with small sizes from tungsten powder, ”said Ivan Pelevin, a representative of the development group, Ph.D.

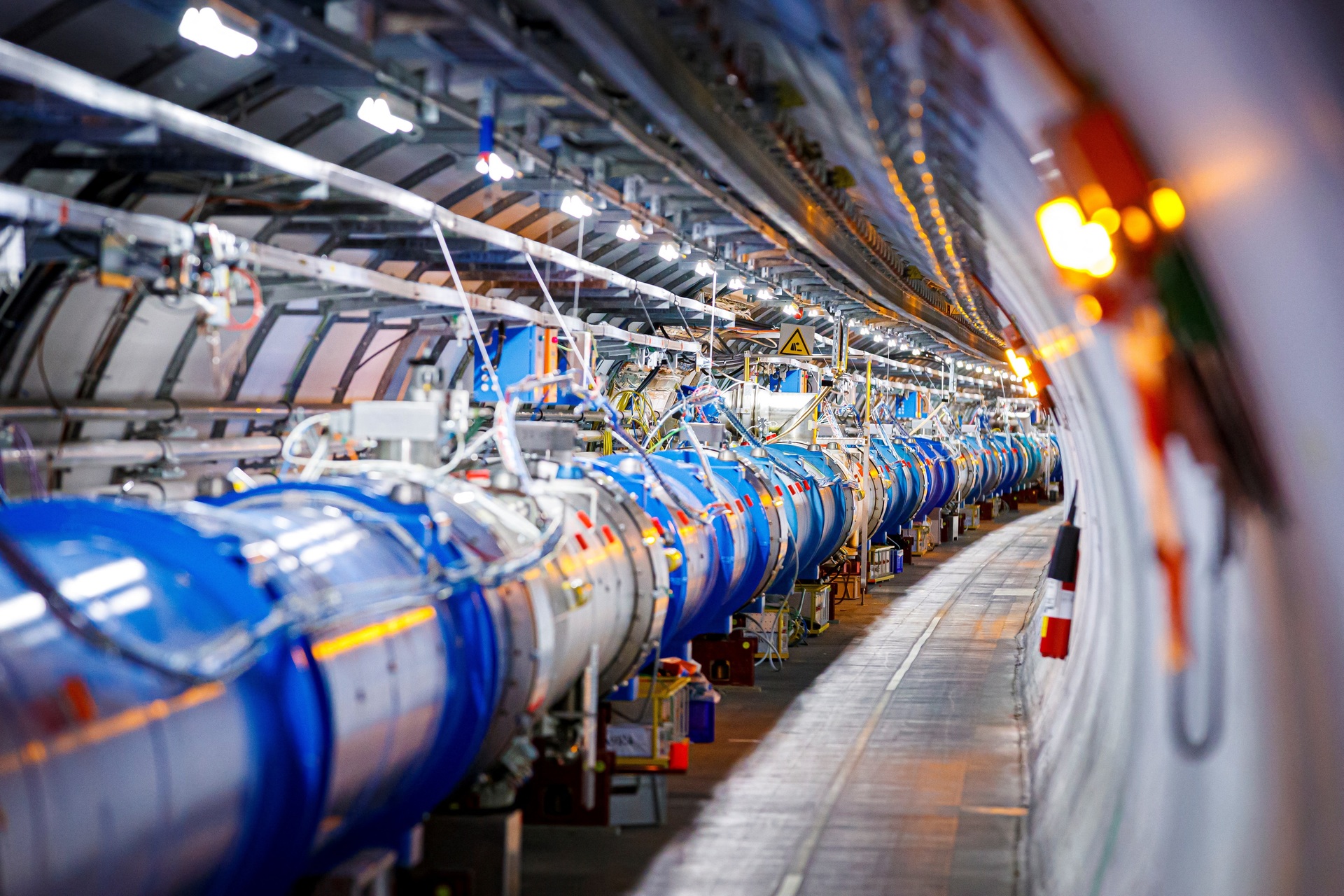

The Large Hadron Collider

AFP

© VALENTIN FLAURAUD

Tungsten is needed in many modern branches of science and industry - from metalworking and aerospace to engine building and medicine.

It effectively absorbs radiation and is little susceptible to corrosion, but it is very fragile, so it is difficult to machine.

One of the most promising ways to manufacture parts from such a material is 3D printing.

“Despite the refractoriness of tungsten, we managed to select the technological parameters of 3D printing for the production of thin-walled parts from it using selective laser melting technology

.

We have studied in detail how tungsten melts when exposed to laser radiation.

As a result, we determined that it is possible to print ultra-thin parts on a 3D printer as efficiently as possible from tungsten powder,” said Ivan Pelevin.

According to the developers, in the future, this technology can be used to create a new generation of calorimeters (high-energy particle detectors) for experiments at the Large Hadron Collider at CERN and at Russian particle accelerators.

In addition, thin-walled tungsten screens printed on a 3D printer can be used in an innovative method of treating oncological diseases: a non-invasive effect on a tumor using high-energy charged particles.

The technology will focus the flow of particles and more accurately direct them to the affected area.

According to scientists, this will significantly increase the effectiveness of therapy and avoid the negative effects of hard radiation on neighboring healthy tissues.

The researchers note that in the future, the thin-wall printing method will be applicable to other refractory materials.