Scientists from NUST MISIS and the Institute for Problems of Microelectronics Technology of the Russian Academy of Sciences have developed a nanocomposite material based on silicon and graphene for hydrogen batteries for electronic devices.

This is reported in the journal Microporous and Mesoporous Materials.

The research team was faced with the task of creating multifunctional cathodes of hydrogen-air micro-fuel cells for portable electronics, which could be integrated directly into printed circuit boards of devices.

As the author of the study, associate professor of the Department of Materials Science of Semiconductors and Dielectrics at NUST MISiS Ekaterina Gosteva, told RT, hydrogen power supplies are very promising and environmentally friendly, but currently they are not widely used in microelectronics, and their use has a number of limitations.

In particular, electrolytic membranes made of Nafion fibrous polymer are now used in such micro-fuel cells.

A significant drawback of such a material is its ability to absorb water, which is formed as a result of the operation of a hydrogen-air power source.

As an alternative, Russian scientists have proposed waterproof cathodes based on silicon and graphene.

“Rockets fly on hydrogen fuel, cars are already being produced and aircraft on hydrogen cells are being developed.

How to make a miniature hydrogen-air power supply for a regular mobile phone?

Our fuel cell is made of silicon, just like a computer chip.

For example, when creating a printed circuit board, such an element with the required amount of hydrogen can be included in its structure, "Ekaterina Gosteva explained in an interview with RT.

According to the researcher, a graphene layer is used to stabilize the silicon in the cathode structure.

Previously, scientists tried to apply it to the surface of the material, but nanoporous silicon was still gradually destroyed under the influence of water or weakly alkaline solutions.

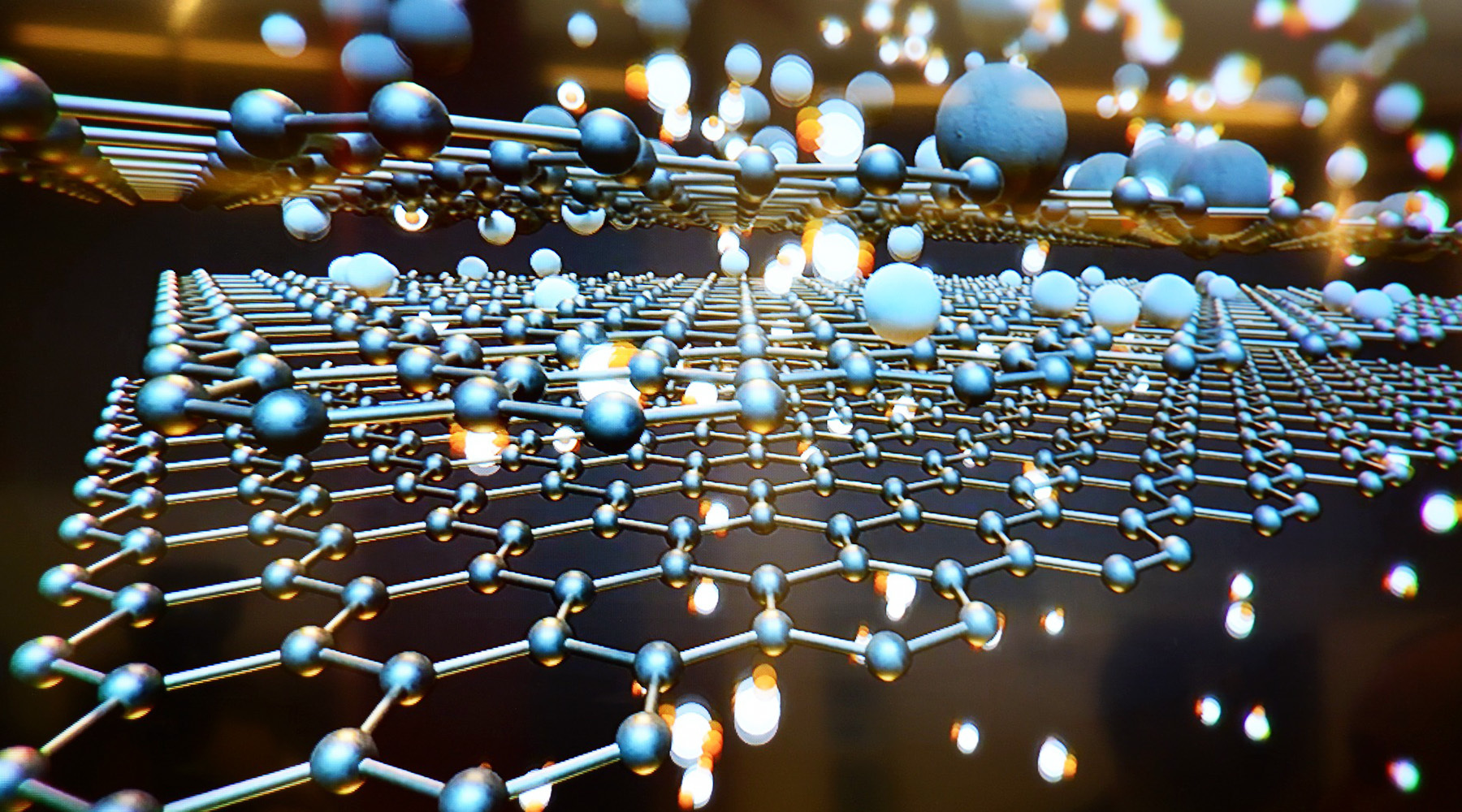

Using the new technology, for the first time in the world, it was possible to create a graphene coating throughout the entire depth of a porous silicon structure - from nanopores at the surface to a macroporous framework.

To create the coating, chemical vapor deposition from alcohol vapor was used, in the process of which a special regime of pressure drops was applied.

The new technology was the first in the world to create a graphene coating throughout the entire depth of the porous silicon structure.

© NUST MISIS

The unique technique, the researchers note, made it possible to radically improve the properties of silicon porous structures and provide them with greater durability, efficiency and electrical conductivity in comparison with unmodified analogs.

“We have proposed a unique method for creating multilayer graphene coatings on the inner walls of pores throughout the entire depth of the silicon structure.

There are no other methods of producing electrodes for efficient micro-fuel cells today.

Current sources of this kind can not only provide a long-term backup power supply for equipment, but over time, they will probably replace the batteries, ”said Ekaterina Gosteva.

In the course of laboratory experiments, scientists have shown that due to the formation of an additional relief inside the pores, the area of the useful surface of the material produced using their own technology has increased more than three times.

In the future, the researchers intend to adapt the technology created in the laboratory for industrial applications.

The team plans to use a silicon-graphene composite as electrodes for micro-fuel cells and try a new technique for printing microcircuits.

According to Ekaterina Gosteva, they will also try to develop material for catalysts to replace the rare and expensive platinum.