- Eleonora Moiseevna, with the latest achievements of your department - the creation of the first virtual plant in Russia, a digital twin of a chemical enterprise. What it is?

- At the Department of Information Computer Technologies of the RCTU, we have created a new digital virtual plant for the production of methanol, taking into account the essence of all phenomena and processes occurring at such an enterprise. The work was carried out with the support of an American corporation producing electronic control and automation systems, as well as with the participation of a large Russian chemical enterprise.

As a result, a dynamic model of the scheme of a chemical plant was created with the ability to control technological processes, a central core was developed - a program that provides the relationship of the database of the scheme of the plant with a web interface and a virtual environment. Then the devices of the technological scheme and the whole plant as a whole were presented in the form of virtual reality objects.

- Virtual chemical plant

- © Screenshot from video: Department of ICT, D.I. Mendeleev / Youtube

- What is the use of such digital twins?

-Based on the model of the technological scheme, it is possible to test the operation of the enterprise in different modes and significantly increase its productivity. So, at the last stage of work on the creation of a virtual plant, we developed and implemented scenarios of emergency situations and their elimination. In fact, the production simulator merged with a virtual representation of the entire process chain. The simulator can be used to train production operators. The presence of a virtual representation of the devices and their placement with reference to the terrain where the object will be built makes it possible to eliminate many errors in the 3D design of the workshop.

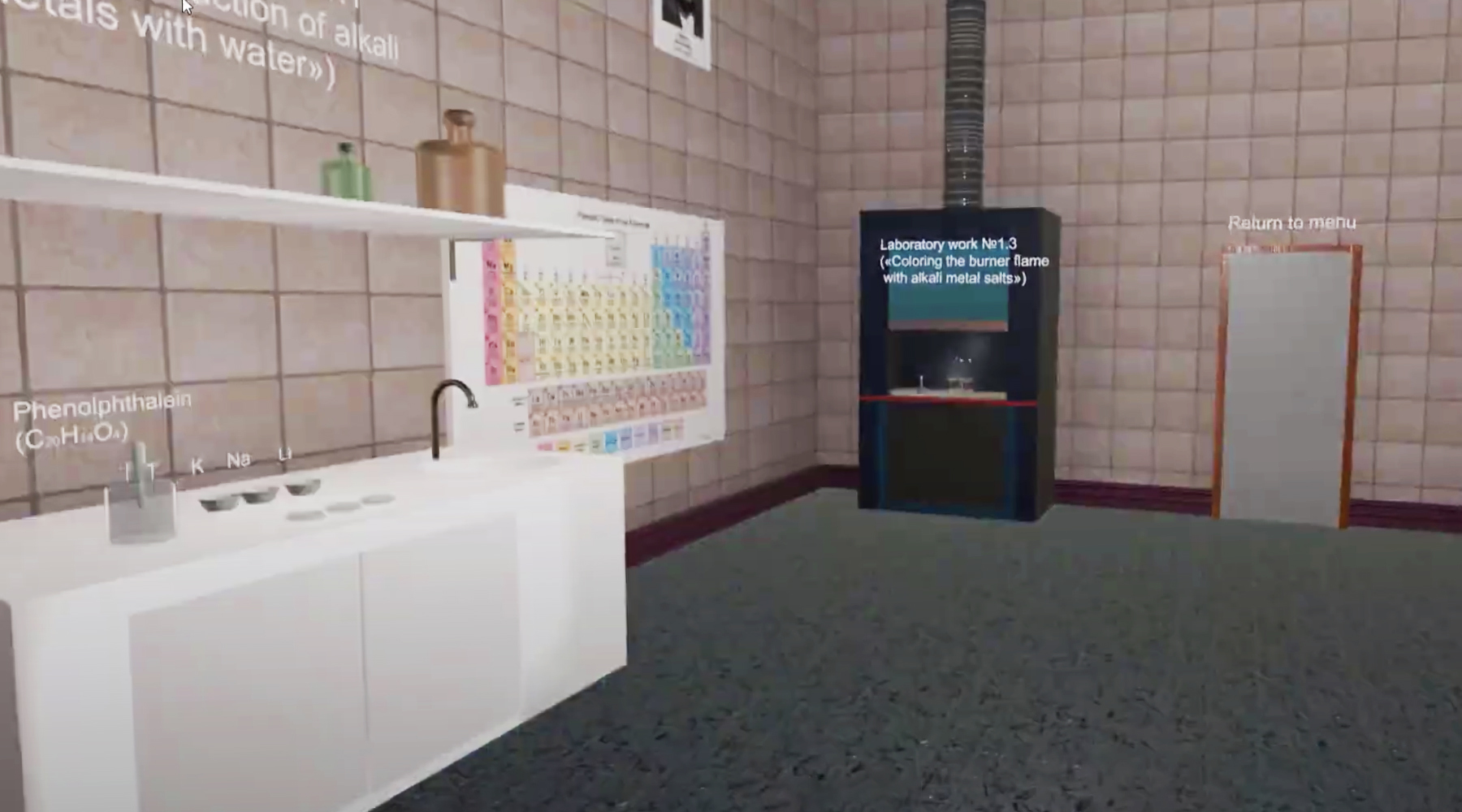

We also developed a virtual chemistry workshop with a VR helmet. It, of course, does not replace the real one, but it is a good help, a kind of simulator for conducting chemical experiments, especially in the context of distance learning.

- Virtual chemistry workshop

- © Screenshot from video: Department of ICT, D.I. Mendeleev / Youtube

- The RCTU has created its own model for predicting the development of the COVID-19 pandemic. What is its difference from others?

- We use nonlinear dynamics methods to simulate the spread of coronavirus infection. Basically, in Russia and in the world, SIR and SEIR mathematical models are used, where various possible states of a person are considered: S - healthy, E - infected during the incubation period or asymptomatic, I - infected in the active stage of the disease and R - deceased or recovered with immunity ( depending on interpretation).

We have abandoned them. In conditions of uncertainty and rapid response, to assess the situation and calculate active infected, models with the smallest number of determined parameters were needed. Our model consists of a system of discrete logistic equations with two determinable parameters: growth rate and system capacity. The growth rate is determined at the very beginning of the spread of the epidemic. It can change in accordance with the restrictive measures adopted in the country. The capacity of the system is the maximum number of residents of a country (city) who can potentially get sick. It is determined at the end of the first third of the period - from the beginning to the peak of the spread of the epidemic.

- What numbers does your model give, can you make certain predictions with its help?

- We have quite accurately identified the peaks of the epidemic in Italy, Spain, Portugal, Japan, Germany, Vietnam, Czech Republic, Brazil and other countries. A number of countries are ending the epidemic, have passed the peak. However, India now has the largest system capacity. The peak of the epidemic there is expected on August 25, 2020, and on this day, an increase in the number of infected people is expected there by 68 thousand people.

The first wave of COVID-19 spread in India will bring 6.5 million infected, which is a lot. Also at the moment we are conducting recalculation for such countries as the USA, Brazil, Russia.

- The mathematical model of the RCTU showed that the wave of the spread of COVID-19 in India will bring 6.5 million cases

- Reuters

- © Amit Dave

Note that the concept of a wave is terminological. And only the superposition (overlay) of several waves gives a good result in terms of the coincidence of the calculated and actual data.

In China, strict restrictive measures were taken, which were literally respected by everyone, so the spread of the epidemic fell on a single wave.

In Italy, the spread did not fit into a single wave, there were large errors in the calculations of daily increases and the number of infected.

According to our calculations, the spread of the epidemic in the world is currently keeping within the superposition of five waves. The first wave characterized the spread of the epidemic in China, the second mainly covered European countries, the third - Russia and some US states. The fourth and fifth mainly reflect the spread of the epidemic in the United States, Latin America and South Asia. According to the latest calculation, the number of those infected from the superposition of these waves will be about 21 million inhabitants of the planet. The end of the fifth wave, which is not the last, is expected at the end of November this year. We recalculate the data every ten days, as new waves may appear.

- Are there risks that you consider underestimated?

- There are such risks. For example, according to our model, Moscow is now experiencing the fifth wave. With the first wave, we went into quarantine, then waves arose due to Easter and May holidays. The first wave was of the largest capacity - 1 million inhabitants, it brought 75 thousand infected, each subsequent one was smaller. The penultimate one, with a capacity of 150 thousand inhabitants, arose in May, when industrial enterprises started working. It brought 15 thousand infected and, if the restrictions were maintained, was supposed to end in July. However, the latest recalculation showed that on June 16 there was another wave with a capacity of 1 million inhabitants, which carries 36 thousand infected and increases the number of infected Muscovites to 260 thousand.

The end date for this wave is November 2020. Therefore, we must understand that the epidemic in Moscow is not over. I advise everyone to wear masks in crowded places, transport, shops, and so on.

- Mendeleevs under your leadership have achieved great success in the field of mathematical modeling. What other chemical and technological processes do your experts calculate?

- The department develops directions for modeling a wide class of fuel cells, creating software in the field of obtaining nanocomposites, as well as fundamental research in the field of nonlinear dynamics and thermodynamics of irreversible processes, modeling in the field of increasing oil production.

On the basis of the models we obtained, it was possible to improve the characteristics of a wide class of fuel cells. A technology for energy generation and wastewater treatment has been developed on the basis of a microbial fuel cell.

Optimal modes of obtaining new materials - nanocomposites - based on aluminum oxide and silicon carbide were also found. Such composites are reinforced with reinforced carbon nanotubes and have improved physical and mechanical properties. Mathematical methods were used in the development of physical and chemical cyclic impact on the bottomhole zone of low-debit wells. They lead to a significant (fivefold) increase in oil production.

- How is the digital transformation in the chemical industry in general going?

- Currently, the transformation of production and business processes with the help of digital technology tools is actively taking place. They are based on the use of big data (big data) and on methods of machine learning (artificial intelligence).

On the basis of analytical models, companies choose the optimal technological mode, build a repair schedule, and avoid equipment breakdowns.

Platforms for working with augmented reality are being developed, image recognition systems for displaying hints on equipment, the industrial Internet of things is being introduced - for example, wireless sensors are installed on pipes that allow you to replace regular bypasses.

- Computer methods are also used to create new materials, including composites with previously unseen properties ...

- It is true that new materials can be obtained on the basis of computer design. For example, a number of crystal structures are taken for which a quantum mechanical calculation is performed. Then the neural network is trained on a set of features of each of these structures to create a connection between features and energy. When using a neural network, calculations are reduced by almost 10 thousand times. So, after analyzing the structure of boron, scientists predicted a new structure for gamma boron - one of the hardest substances.

The department is engaged in modeling the processes of obtaining nanocomposites with high strength properties. These processes include the method of pulsed plasma sintering. With this method, it was possible to obtain a nanocomposite based on aluminum oxide with a high volume content of carbon tubes. They provide high strength properties and lower material density.

- Special training programs are used to train technologists

- Gettyimages.ru

- © SrdjanPav

- Long-distance work and distance learning have become more in demand than ever. How does computer information technology reduce the economic costs of research, expand the opportunities for training specialists in the chemical industry?

-Computer technologies cannot replace real experiments, but they are a powerful assistant and significantly reduce research time. Determination of optimal experimental modes is much faster using a mathematical model.

Teaching technologies also show high efficiency. Our virtual chemistry workshop (without a VR helmet) out of 170 works during the quarantine was used three to four times more often, the number of visits was about 10 thousand. Of course, this is a great support in teaching chemistry to high school students and schoolchildren.

As for the training of specialists in the chemical industry, for their training we create simulator programs to understand the relationship of technological processes and study the operating modes of various devices.