Employees of Moscow University (Lomonosov Moscow State University) and the Institute of Applied Physics of the Russian Academy of Sciences (Nizhny Novgorod) have developed a new technology for the manufacture of biomarkers for medical diagnostics. This was reported in the journal "Quantum Electronics".

In science, silicon is known not only as the basis of microcircuits and solar cells. Researchers are showing interest in this low-cost technology material for biomedical purposes. Ultra-small particles of silicon (nanostructured silicon) are used to diagnose tissues and cells, as well as in therapy.

“We have developed nanostructured silicon manufacturing technology for medical diagnostics. Silicon particles are markers that will make it possible to see structural heterogeneities hidden in an opaque body environment, such as tumors, ”Stanislav Zabotnov, the main author of the work, associate professor of the department of general physics and molecular electronics at the Moscow State University, said in an interview with RT.

According to him, nanoparticles entering the body can accumulate in malignant neoplasms in the body, and this can be detected using special optical monitoring tools.

The scientific problem was the lack of effective technology for the production of non-toxic nanostructured (less than 100 nm in size) silicon, suitable for relatively safe introduction into the body and subsequent excretion. The grinding of silicon structures in most cases did not allow obtaining clusters of the required size, and using colloidal chemical synthesis, the nanoparticles were obtained with a large number of toxic impurities.

The problem of producing safe particles of the right size was solved by the method of pulsed laser ablation of silicon in liquids and gases - by "firing" silicon particles with laser pulses. Scientists were able to create markers of a given size, including units and tens of nanometers, but a significant problem was the insufficient, relatively small number of nanoparticles at the exit.

However, this limitation was overcome by using the method of manufacturing the initial films of porous silicon instead of the commonly used crystalline silicon wafers. Using a simple and cheap method of electrochemical etching, it was possible to obtain a material that increased the mass yield of silicon nanoparticles by several times, the researchers noted. Then they proceeded to the first tests.

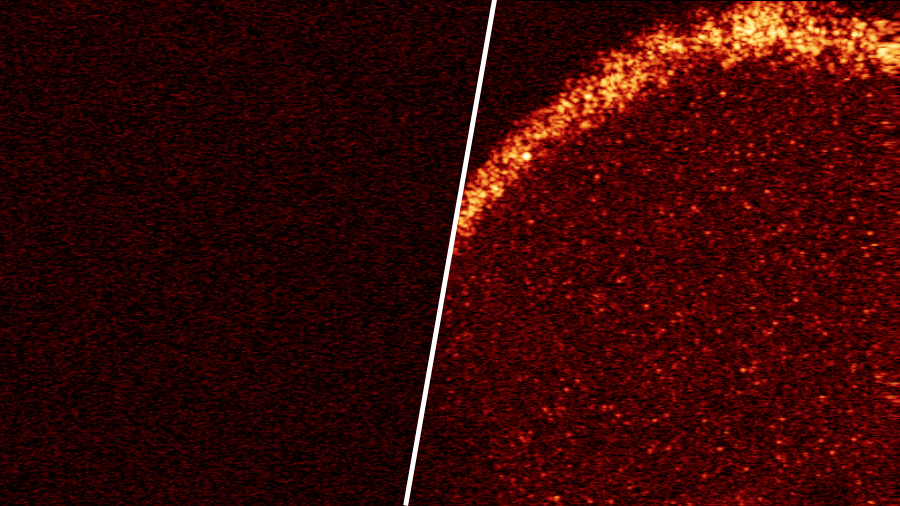

“Silicon nanoparticles made using our technology were deposited on the surface of an agar gel imitating biological tissue. Due to the inherent particles of strong light scatteringwe received high-contrast images of heterogeneities. This is an important step in solving the problems of biomedical diagnostics - visualization of biological and biosimilar tissues, ”said Zabotnov.

- Transparent agar gel on the left without biomarkers, on the right - with embedded silicon nanoparticles

- © Moscow State University M.V. Lomonosov / Institute of Applied Physics RAS

As the scientist emphasized, one of the most harmless methods of visualizing biological objects, the method of three-dimensional optical coherent tomography, was used to observe the introduced particles. Silicon itself is also, he said, relatively safe. Unlike radioactive particles that are often used as markers, it does not have a harmful effect on surrounding tissues and is well excreted.

Further studies of the new technology were suspended due to the coronavirus pandemic, but will continue in animal experiments in 2021, Stanislav Zabotnov said.