Entering the smart phone industry

Researchers from Khalifa University develop five-dimensional lenses

Image of researchers at Khalifa University developing 5D lenses

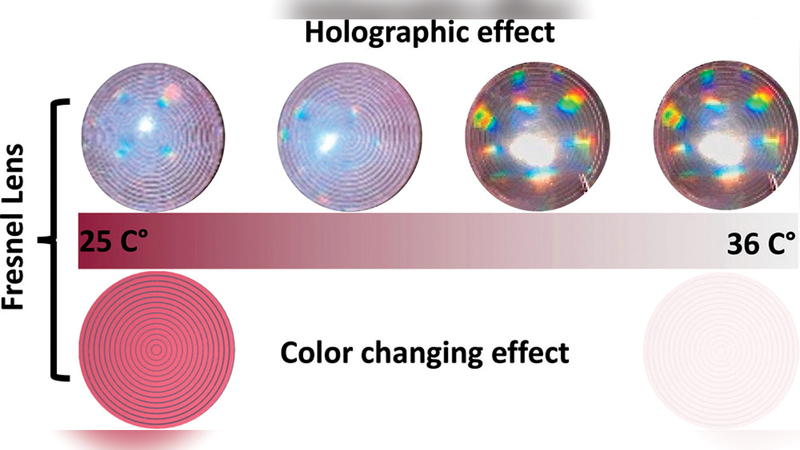

Khalifa University of Science revealed the success of a team of researchers from the Department of Mechanical Engineering, using 3D printing techniques, in developing five-dimensional Fresnel lenses, adding a color-changing feature and three-dimensional diffraction.

The team included Associate Professor Dr. Haider Butt, PhD Student Murad Ali, and PhD Researcher Dr. Fahd Alam.

The team published its findings in the international journal ACS Materials.

Dr. Haider Butt explained that the use of Fresnel lenses aims to create effective beams of rays that extend over very long distances, in contrast to the traditional lenses available in telescopes.

He said that it is also possible to manufacture Fresnel lenses from plastics, such as acrylic, polycarbonate materials and glass, which makes manufacturing an economical and easy process.

Haidar stated that "Fspheral Fresnel lenses are innovative, characterized by their improved materials, and are now entering into many fields, including magnifying lenses, smart phones, photovoltaic panels, ultrasound devices and miniature spectrometers."

Silicone Fresnel lenses can also be used in aerospace-related applications, such as glass-shielded solar collectors, where they can be easily produced by injection-moulded and pressed.

Haidar added: “The lenses that we developed have unique optical properties, but we seek to do more developments to reduce the thickness of each layer in the lens to improve optical performance, and add more softness to the surface of the lenses through the use of various processing techniques,” noting that the research shows 3D printing capabilities in manufacturing micro-optical parts that can be used for promising applications in the fields of sensing and communication.

Haidar pointed out that 3D printing is a promising technology that contributes to the exploration of design strategies and the degree of complexity in Fresnel lenses.

It also allows the production of multi-material lenses for sensing, and for multi-functional optical purposes, pointing to the reliance in this research project on manufacturing by 3D printing, as they developed five-dimensional “Fresnel” lenses so that the fourth and fifth dimensions perform the functions of three-dimensional thermal sensing.

It is worth noting that Fresnel lenses focus light depending on a surface capable of refracting light, such as the ability of a thick glass lens.

The team published its findings in the international journal ACS Materials.

Follow our latest local and sports news and the latest political and economic developments via Google news