The first large-scale domestic cruise ship began to build new equipment and new technologies to drive the development of the industrial chain

CCTV News: Large cruise ships are known as mobile "modern maritime cities". Due to the weight control requirements, steel sheets with a thickness of less than 8 mm are mostly used as the main material for the cruise ship’s main activity areas and cabins. In order to avoid The thin plate is deformed during the processing, and the developers have adopted a number of new equipment and new technologies.

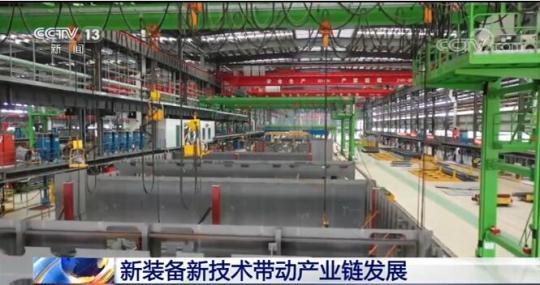

CCTV reporter Xu Yang: Compared with civilian ships, another feature of cruise ships is that the use of thin plates accounts for more than 75% of the steel plates used in the entire ship. The assembly line you see now is the laser thin plate production line. This production line can not only improve Production efficiency, and more importantly, can improve the flatness of ship plates.

Wang Jincheng, Minister of Shipbuilding Department of China Shipbuilding Waigaoqiao: The thin plate assembly line mainly uses laser and robot equipment as the control of our heat input, reduces the deformation of the sections, and controls the accuracy of the entire ship. Then the stability of the entire ship will become more stable. Excellent, passengers will feel very comfortable living on it.

According to reports, the thin plate manufacturing center has achieved full coverage of the 5G network, and realized intelligent management with the help of industrial Internet of Things technology, providing intelligent power for the construction of cruise thin plates.

As one of the most difficult ship types to design and build in China’s shipbuilding industry, the cruise ship construction industry has a long, wide coverage and strong driving force. The design and construction of my country’s first large cruise ship will play a positive role in the development of my country’s local cruise supply chain system. Leading role.